How Humanoids Are Shaping the Future of Work

Stepping from the pages of science fiction into the real-world factory floors and logistics centers, humanoid robotics is on the verge of a dramatic transformation. What were once captivating tech demos are now becoming a realistic solution for a new era of automation and human-robot collaboration

In this article, I examine exactly where I stand on this journey, exploring the latest breakthroughs, the powerful economic forces driving the revolution, and the challenges that lie ahead.

An Era of Convergence: Why the Humanoid Breakthrough is Happening Now

The sudden surge in humanoid robotics isn't the result of a single innovation, but rather the simultaneous and explosive maturation of several key technologies. This convergence has created the perfect conditions for the current revolution.

-

AI and Sensor Fusion: The latest generation of AI models, including large language models (LLMs) and advanced computer vision, allows robots to do far more than execute pre-programmed routines. They can now understand verbal commands, visually assess their environment, and dynamically adapt to changing circumstances in real time.

-

Advances in Hardware: Actuators (the robots' "muscles"), batteries with ever-increasing energy density and faster charging, and lightweight yet durable materials have all reached a critical level of maturity. This makes it possible to build human-scale machines that are efficient, agile, and robust.

-

Economic Pressures and a Surge in Investment: Labor shortages in the developed world, shifting demographics, and the drive for more resilient supply chains have created immense economic demand for advanced automation. Recognizing this, tech giants like Microsoft, NVIDIA, and Amazon, along with venture capital, are pouring unprecedented funding into the most promising companies in the field.

A humanoid robot is a machine designed to emulate the human body, typically with a torso, two arms, and two legs. This form factor provides two revolutionary advantages. Firstly, it offers universality: unlike fixed-purpose industrial robots, a single humanoid can be programmed to perform a wide variety of tasks, serving as a general-purpose platform. Secondly, and perhaps its most significant economic benefit, it requires no costly infrastructure modifications. It is designed to operate in environments built for people—navigating stairs, opening doors, and working at existing stations—allowing it to be integrated as a "drop-in" solution into current workflows quickly and cost-effectively.

The Key Players on the Global Stage: A Snapshot of Progress

The global race is fiercely competitive, with several companies vying for market leadership, each with a unique approach.

-

Tesla Optimus: Elon Musk's vision is centered on a general-purpose robot designed for mass production. Leveraging Tesla's advanced AI, sensors, and battery technology, the primary goal is cost-effectiveness, paving the way for widespread adoption first in factories, and eventually in homes.

-

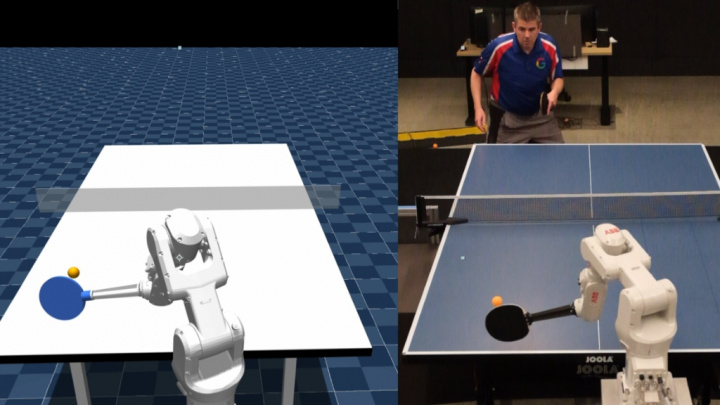

Figure AI & Its Partners (OpenAI, BMW): The Figure 01 robot uses cutting-edge models from OpenAI for its reasoning and communication capabilities. Through a landmark partnership with BMW, its robots are already being deployed in a US automotive plant to prove their viability in handling "dull, dirty, and dangerous" tasks.

-

Boston Dynamics Atlas: Long considered the gold standard for dynamic mobility and agility, the latest all-electric version of Atlas is shifting its focus from acrobatics to performing real-world tasks that require strength and manipulation, marking a turn toward commercial application.

-

Agility Robotics Digit: Purpose-built for logistics, Digit is already being piloted in Amazon warehouses to move totes and manage inventory. Its design is explicitly optimized for efficient material handling in environments designed for people.

-

UBTECH Walker S2: This Chinese robot tackles a key operational hurdle: continuous operation. While most robots must return to a docking station for hours of charging, creating downtime, the Walker S2 can autonomously swap its own battery. This type of practical innovation is essential for enabling true 24/7 industrial operations.

From the Factory to the Front Door: Applications and Cloud Intelligence

The initial proving ground for humanoid robots is unquestionably manufacturing and logistics. The automotive industry, a historic pioneer in automation, is once again serving as the primary testbed. Alongside BMW and Mercedes-Benz, Chinese giants like BYD and Nio are also actively integrating these robots onto their production floors.

The efficiency of these individual robots is magnified by the software platforms running in the background. Systems like UBTECH's BrainNet act as a cloud-based "hive mind." It can coordinate and schedule an entire fleet of robots in real-time, sharing navigational maps and optimizing tasks across the system. This central intelligence allows the robots to function not as isolated machines, but as a cohesive, synchronized workforce.

The Economic and Geopolitical Landscape: Robotics as a Strategic Sector

The development of humanoid robotics is inseparable from global economic and geopolitical trends. China, already the world's largest robotics market—accounting for over half of all global industrial robot installations—is strategically positioning itself to lead in this high-tech sector as well.

-

Market Size and Growth: The government has set an ambitious national goal of mass-producing humanoid robots by 2025. Projections show the market expanding from tens of billions of dollars today to a multi-hundred-billion-dollar industry in the coming years.

-

Government Strategy: Initiatives like "Made in China 2025" and the "Robot+ Action Plan" are fueling the sector with massive state investment and policy support.

-

Technological Self-Reliance: A decade ago, China was heavily dependent on imports. Today, domestic manufacturers command over 50% of their home market, signaling a profound shift toward technological independence.

The Road Ahead: Future Vision and Unsolved Challenges

The future is bright, but the challenges remain significant. While research from BofA Global Research predicts the hardware cost of a humanoid robot could fall below $15,000 by the end of the decade, several hurdles must be cleared.

-

Software Robustness: Robots must operate reliably and safely not just in ideal conditions, but also when faced with chaotic, unexpected "edge cases" of the real world.

-

Fine Motor Skills and Dexterity: Replicating the complexity and dexterity of the human hand remains one of the most difficult engineering challenges.

-

Cost-Effectiveness and ROI: Until mass production is achieved, companies must prove that the high initial investment in robots delivers a clear and timely return.

-

Societal Integration: Addressing the impact on the labor market, ensuring safety, and navigating complex ethical questions will be crucial for widespread public acceptance.

Conclusion

Humanoid robotics has reached a true inflection point. The convergence of advanced AI, mature hardware, and massive economic investment has ignited a self-perpetuating cycle of progress that is now irreversible. While industrial and logistics applications represent the present, the long-term vision is of a general-purpose assistant that can operate in every segment of society. The global race between China, the United States, and other tech hubs is not just about building the next generation of machines—it's about shaping the future of labor, production, and the global economy itself.